Replace drill press table lift handle

Recently noted and replaced cracked table lift bracket. When reassembling is when I noticed the crack in handle. Found replacement handles but as it could stand to be longer going to look at making a new one. This is on my old Central Machinery (Harbor Freight) 16 speed, 17" drill press.

Rather odd crack, its full length where plastic contacts metal sleeve but hasn't yet gone through outer surface of arm. Regardless-needs fixing

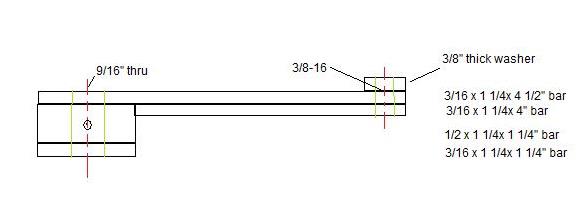

Going thru scrap I found a 1 1/4" square piece of 1/2" bar with a 9/16" hole in it. Fits drill. I could add flat bar to it to make handle. I can build up needed thickness to more match thickness of old handle so it doesn't wobble on shaft. So that's where were going.

Sandwich. As I have some 3/16"x1 1/4" bar I'm using to build up handel using the 1/2" as base. Overall it'll be about inch longer. Welded short piece same size as the "base" for added thickness. Then drilled it using hole in base as guide. Then added full length piece to top then shorter piece underneath that's butted to 'base'. Welded it all out. Plan is once all together to bend top 2 pieces of flat bar to get the stand off of original handle.

Welded it out and then the plan changed. Originally was going to taper arm but decided to decided to kinda match the curves on my old post drill. Used plasma, most of the welds cut off but still holding together.

As you can see was having heck off a time welding, I finally realized when I switched from mig shielded wire to gas I forgot to change polarity on machine... doh. Almost all will get ground out, just dumb.

Drill and tapped handle 3/8-16 thru. Reusing original knob but it has slightly larger metric (and wore) thread. I can recut it to 3/8 thread. Bolted on the spacer for handle standoff. Weld it to arm at end then fully radius the edges of arm. Figured be easier even having to go back after bending to do most grinding while straight.

radiused and bent. Never heated multiples layers to bend before. Drilled and tapped with 2 opposing set screws. I'm still shaping here. Though almost done a lot of gouging where the seam between 2 bars opened up, rewelding and re grinding. Just a lot of back & and forth till happy. I wasn't sure about bending the welded pieces, none cracked but they actually tore out of base metal at the bends. Then on edges where first pre welds were almost entirely removed when plasma cut. Something new and different.

I was liking the covered hole and not seeing the shaft but even with 2 set screws not very stable on shaft. Plus gear shaft can move in and out with out handle pretty close. Needs a shim behind it. Anyway drilling thru as planned.

I have about a 1/2" greater stand off which is good with extended length. Bends took more than allowed so its only just over 3/4" longer than factory handle.

A lot more hand filing smoothing, few more welds- and painted.

I wouldn't have done this if it had not cracked, but its easier to use. Actually a fun project..Now to finish the tables counter weight...

Part 3 finishing table counter weight that got put on hold to do this

Part 1 Table lift bracket replacementwhere this all started

Back to top of page

Back to shop tool mods

Back to Our shops home page