Continued table mods

. 2022-original addition of table leaf for use for walking foot sewing machine. Sewing machine table leaf

Details: 1.)Finalizing leaf addition to table I had noted area behind leaf support legs at side of table under leaf. Occurred to me I could make some small shelves to store thread spools and other small items, freeing up space on tables main shelf.

Details: 2.) I need to add a full backing to legs for stability and strength.

And 3.) add a second pair of pivot 1x2s on either side of legs. The bolts supported on just one end wobble and are wallowing out thru holes.

The 1x2 legs aren't very strong, flex. When looking to make sure adding spreader or backing between the legs doesn't cause any inference issue is when I saw possibility of adding shelves.

To add full backing to legs it could only cover distance from where legs contact leaf in dropped position. Or recessed into legs for full length to still fold flat.

The only restraint as far as adding shelves is when the leaf dropped. Shelves could extend no more than 3" from table. Spools are less than 3" in diameter so that would work, at 5" tall might get 2 shelves.

It was raising & lowering table leaf eyeballing shelf addition and leg backing is when I noted how much the pivot bolts were wiggling in holes.

So back on the workbench. Adding the outboard pivot blocks and longer bolts minor, though I dont have any more 1x2 on hand. Realized though once added and the backing board added to legs, the assembly would be strong enough to resist weight of table if lifted by leaf. Which means to lock and secure against breaking something a simpler method can be used instead of the webbing strap to secure. Lot of options, possibly cam over latches...round to it.

On to the shelves...

Used some of the salvaged shelf board leaf was made from. Spent a fair amount of time & effort trying to space and get sizes. Table legs taper outward so successive shelves are a bit narrower and longer. I drilled thru legs and screwed into shelves. 2 upper shelves (table upside down) accessible from out side of table. They are large enough to hold thread spools. Added a small 2" shelf at bottom, accessible from either side though I foresee using it when setting at table reaching thru front opening.

Notched shelves to set flush to inside of legs. I am going to band shelf edges with 1" lattice to give an edge stop. To support shelves at outer edge glued and nail piece of the lattice at front outside corner.

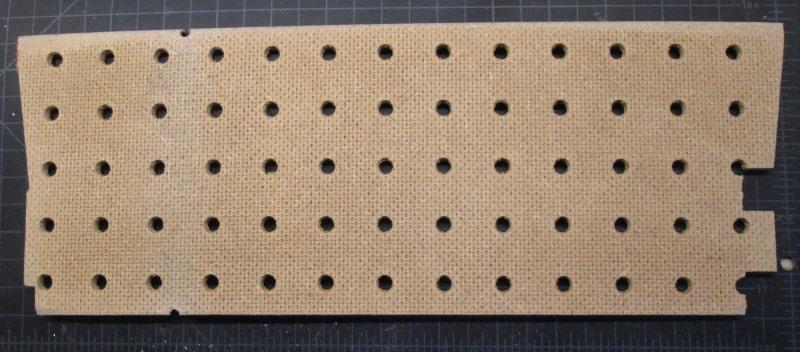

At other end adding full piece of pegboard tapered to match leg profile. Need to notch small shelf, then pegboard will only protrude 1/4" from shelf edge to butt the lattice against.

Decided to use full backing on the legs. Opted to use pegboard. As leaf support only pivots to 30° from vertical hooks will not fall off, allows hanging small bags of supplies. Either side of pegboard can be utilized. Removed the legs and cut 1/4x1/4 notch on inside corners so backing sets flush.

And back on shelves...

Still upside down. Picked up 6' of 1" lattice, will give 1/4" lip on shelves and help keep stuff from walking off.

Did improve appearance. Sand it a bit more, the lattice is more like resawn firing strips, visible saw marks..Oh well 69¢, a foot what do you expect. Probably spent $6 in fuel driving the 5 miles and back, crazy.

Back side of middle shelf. Was going to close this off with pegboard, then decided to just band. However ran out of lattice. So I guess were back to pegboard. As I 'could' access this shelf from inside of table dont know if practical, I cant see it when setting at table. Holding off. Go ahead and stain the lattice while I make up my mind.

Cut pegboard for shelf backing

Think this may have been reason was going to band, matching shape inside of table legs, but got it.

Meantime, replaced Margarets dishwasher. It had 1x2 wood strips in carton bottom so have material to make second pivot supports. (my reward for installing the dishwasher).

Made pivot supports. Clamped to inside of existing blocks to drill thru holes. Then clamped to outside of legs with inside supports and fender washers in place. Add small scrap at other end to keep parallel also with fender washers. Glue and screwed to leaf. Picked up some 3" bolts perfect shoulder length, need to cut off bout 3/8 of thread.

Stained the all the new wood. Assemble in a bit. Ordered some cam over toggle latches or draw latch that hopefully can be mounted. Remove the strap. I think were done with the shelves.

Stained the all the new wood. Assemble in a bit. Ordered some cam over toggle latches or draw latch that hopefully can be mounted. Remove the strap. I think were done with the shelves.

I suppose I should show finished pictures..

back on the floor. Machine reinstalled

Items in place. Bag of 1" webbing and another of velcro on door..

And machine stored, leaf down. Not planned, took a bit more than I thought but well worth the effort.

On to Add leaf locking latches and 4" casters

Back to Consew sewing machine tool mods section

Back to Shop tool mods section