Replace electronic LED flasher with resistors.

Part of making dually fender light flash with signals (Fender light page ) was replacing front signals with LEDs. To address hyper flash I used an electronic LED flasher. 10 months later, flasher failed. Going back to stock flasher with resistors. Below, original install, flasher fail and subsequent fix.original install: I am converting front 3157 signals to LED. My rear taillights fixtures were previously swapped out to LED, they have resistor in line to stop hyper flashing. When I add front LEDs Im going to change Flasher to electronic and not use resistor in front. Remove the resistors in the rear. This will drop the amp load required considerably (4x 3157 incandescent).. , I've read a lot of folks having issues with the electronic flashers so prepared to add resistors back if needed. Hopefully the electronic flasher works. (it did for a while)

Second project is adding front fender marker lights. Now with the converter I can add front markers and have both park and signals. Something I've wanted to do since I converted headlights to '05 style a few years ago. The '05 lights, the side marker is recessed behind lens and cant really be seen well approaching from rear until almost beside them, signal cant be seen at all.

Changing out front turn signal bulbs to LED pretty simple.

Mostly due to all other bulbs are LED and the flash timing (slow to power up and power down verse LEDs which are instant) is quite noticeable. Changing fronts to LED means I can also remove existing resistors on rear taillights, replace flasher with an electronic unit. That's not so simple on a 2000 ish Ford truck. Someone decide to bury it behind the dash?

But done, works, no buzzing/clicking or other weird stuff folks have reported. Long term?... I'm carrying stock flasher and bulbs just incase. Rear taillight resistors left in place and can be reconnected.

- As Noted: about 10 months later flasher started clicking continuously ALL the time.

I can also turn on signals without key? Everything still functions, but the clicking is annoying, being able to turn on signals without key just wrong. This is a common issue with LED flashers. Reinstall stock flasher, clicking went away but have hyper flash. Replace LED with stock bulbs and normal flash.

Could try another unit but Im reinstalling stock flasher relay-reconnecting rear resistors and adding resistors to front signal lights. PERMANENT LED hyper flash fix. Does defeat power savings of LEDS but not primary reason for switching to LEDS.

Picked up resistors for front, looking to install not enough room behind head lights for resistors, even if there was isn't enough wire to splice in resistors. I dont know if resistors HAVE to be across before LED or if anywhere on line will work. As I have leads from signals to added fender lights I'm going to add resistor to that wire, easier than tapping light socket wiring. If it works done, if not its pulling headlights...

That didn't work, wire goes to side marker, though it flashes with signals tapping for resistor had no effect as its comes from output of converter. Using sewing needle tapped wires before they enter the converter (wires direct from signals lights) and it works. Actually better as it'll be simple to mount resistors somewhere other than behind headlights.

Thought Id mount resistors on rad support under the plastic cowl but again not enough room. Resistors CAN get quite hot, melt stuff.

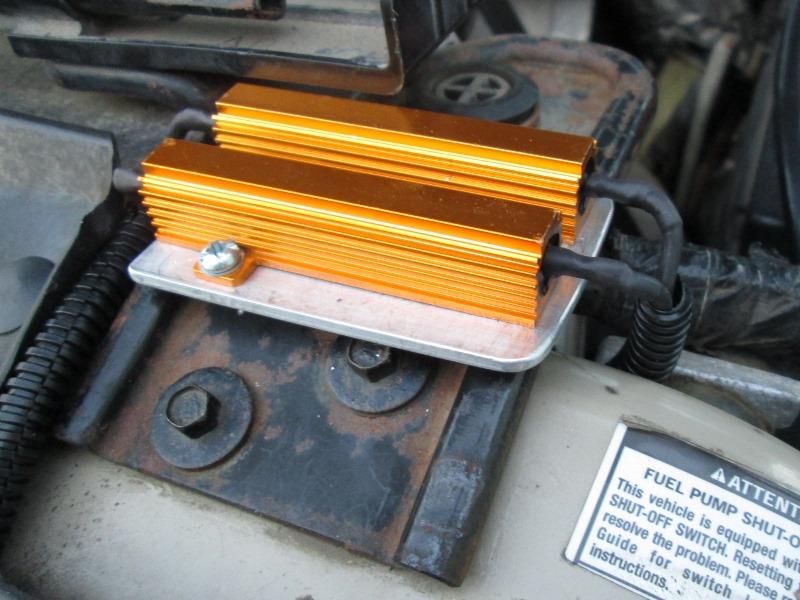

Ended up using a piece of 2" aluminum flat bar, mounted on top of radiator support. 2 screws between resistors thread into drilled & tapped rad mount. Mounted the resistors to it. Ran wires from one end of resistor to existing ground screw. Ran wires from other end of resistors and tapped left and right feeds to converter under plastic cowl. Fixed.

Should have made the mount plate a bit longer, wires on right side rather exposed to getting hit. Terminals exiting resistors wires are connected to are rigid wont flex. May make a cover plate...TBD.

Lastly what I did learn is resistors can be anywhere on circuit after flasher on circuit going to new LED. Just adding extra load to make standard flasher work. In my case using chassis ground also worked instead of tapping ground wire of light.

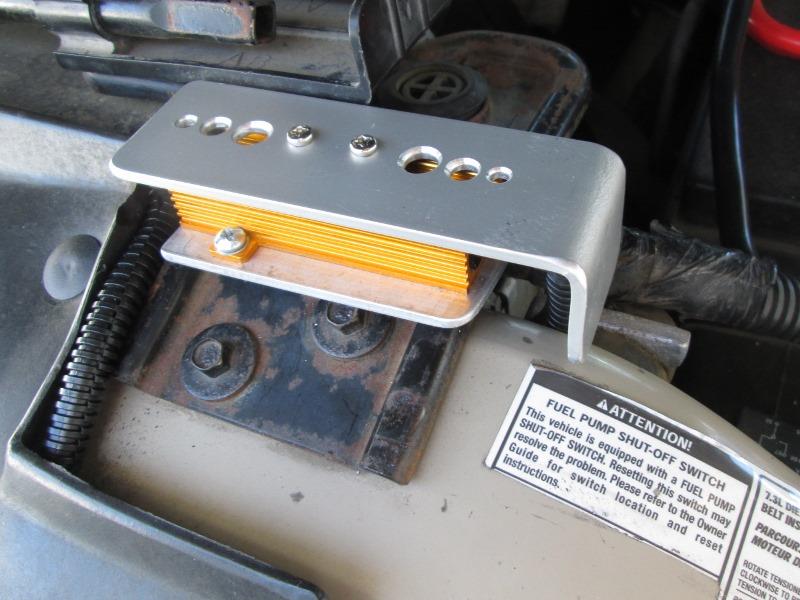

- And cover plate

Drilled for mount screws and bent one end to protect the wires.

Drilling holes to help radiate heat decided to get 'fancy'.

Kinda silly but functional. Wires protected which I was concerned about, may help with heat, gold not so prominent.

Back to Blinking dually Fender light page

Back to our F250 truck page

Back to Ourelkhorn Camper Modifications page