Building a simple 45° miter jig for cross cut sled

Cross cutting material on table saw is not very accurate or safe. Relies on small miter gage that can move, both in rail that runs in slot and the miter head itself flexing. Cuts can vary by a lot. Second is size- either material is so long it overpowers ability to hold straight or material to short to reach blade and securely hold against the miter gage. So built a crude sled. Then built this, 45° jig to cut miters using the sled.

Not a how to- just what I did. There are many videos and plans on YouTube that cover building a cross cut, miter sleds from the most basic to the most versatile with added features. MIne is a simple 45° jig, adjustable would be nice but 90% of the time is just need accurate, repeatable 45° cuts. Also want to securely contain material.

I started with some 2x2's cut to 45°. ( you can see why I need a jig).

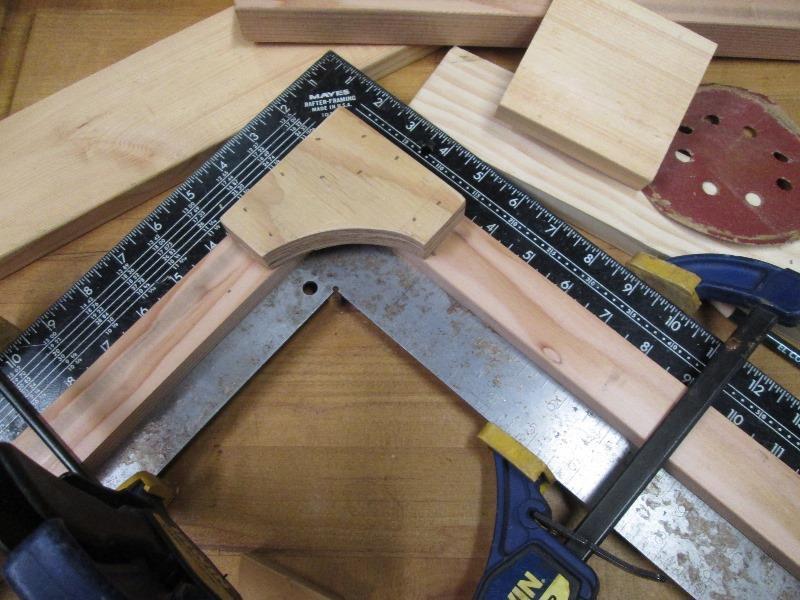

Clamp to squares to ensure at 90° (45° to saw blade)...

Secured with glued & stapled 3/4" plywood block. (NOTE make SURE staples/screws or nails are NOT in blade path)

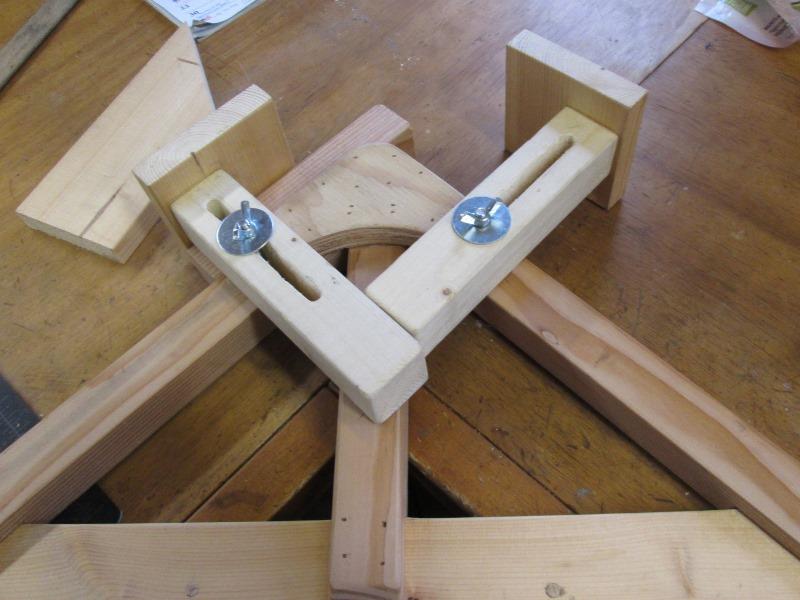

Cut the 2x2's to length that will fit inside sled and allow cutting up to 1x4 material. Then notched in and temporarily attached a 1x4 spreader.

Ran thru saw to verify accurate 45°, glued and stapled spreader.

Added 2x2 block in center, for rigidity and to cover blade. My sled is narrow enough that longer material will simply run off bottom edge.

FYI My biggest limit with this design is I have to cut 45°s from end of board (material cant run beyond blade). Meaning second cut, (board with 45° at both ends)- will need to be trimmed to within 1/2" of final length before cutting miter. Not that big of a deal though will increase waste-cant split a board and use both 45° ends. This reason alone would be a justification for a separate miter sled instead of contained within cross cut sled but this is where I'm at.

To place miter jig added 1/8" piece of ply to center in sled blade slot, added 2 dowels to stabilize. (which I redid later)

Next I want to added material clamps

Laying out built in material clamps

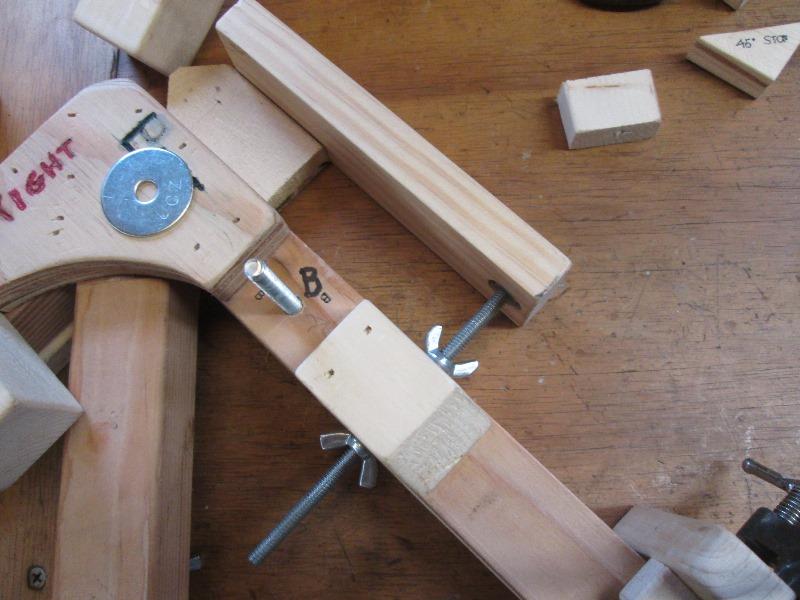

Cut slots in 2x2s that will be clamped with bolts to miter jig

Cut clamps to length so the end of 1 acts as anti rotation support for the other being used to hold material. Using 2x2 as mockup also where I seen limit of material thickness

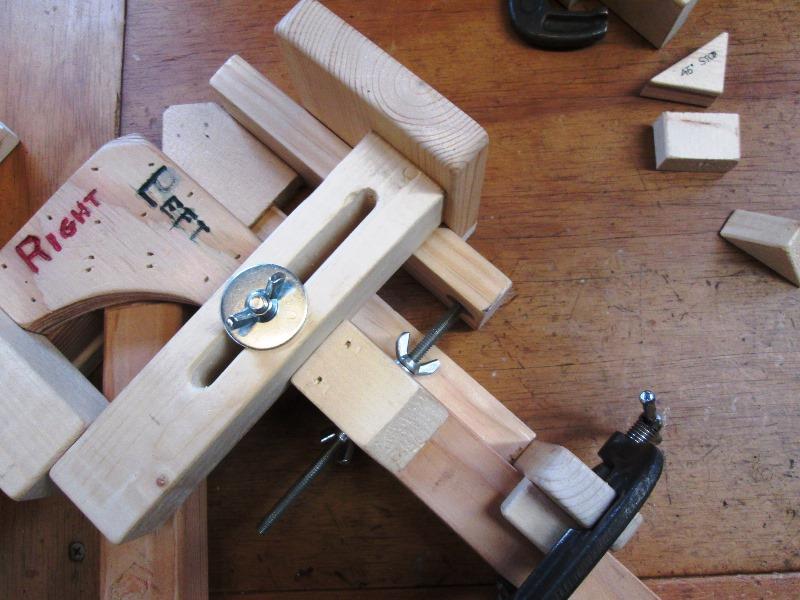

Added 1x2s to bottom to allow up to 2" thick material. Which meant raising locating wedge and replacing dowels with drop in bolts

Added 1x2s to bottom to allow up to 2" thick material. Which meant raising locating wedge and replacing dowels with drop in bolts

And extending clamp faces. (may also help against splitting along grain-these should have been plywood) Added side guides for the clamp arms.

Clamps work really well...now for some stops to make repeatable cuts and help material from sliding away from blade.

My first try was some wood clamps but with bolt over top they squeezed together and just slid off. So using some small C clamps, which barley reach...

Modify as throat depth still too shallow

Ground webs so clamps will slide into slot cut in stop, reaching further down jig sides, shorten foot and screws.

Stop blocks!

Needing to cut small block but cant securely clamp, actually anything shorter than 6" iffy..

So made another auxiliary clamp to reach shorter material

So made another auxiliary clamp to reach shorter material

Used with main clamp, force is applied to end of material and pretty secure.

However even though this an infrequent cut and material not likely to jump up, making a clamp at jig nose to apply downward force. Awkward holding down with push stick. Not likely material would jump up but 'could'. Thrust is to make allowances now instead of while in 'the moment' and jury rigging to accomplish something, which invariably ends up even more sketchy.

Stained, dropped in couple of pieces of pegboard. probably notice labeling, I kept cutting stuff backwards...

An adjustable angle miter jig would be nice, but for now this works. Plus I do have a miter saw for small trim work and that usually is where odd angle come into need.

Just a couple of youtube videos to get you started on your search "table saw 45 degree jig"...

https://www.youtube.com/watch?v=T0F7mgcipZ8

You can get as basic or optioned out as you want..

Back to work...

My other table saw stuff

Link to The cross cut sled build

Link to Vertical miter jig

Back to Our shops tool mods section