Replace handle on drill press vise with folding handle

Merging of wants. Cross slide handle that sticks out and cut off knurled handle that I cant throw away.

The handel on my drill press cross slide sticks out quite a bit- been there for years but its right in the walkway and invariably often as not run into it. Ground end round so it doesn't cut, finally resorted to a tennis ball.

Always wanted to replace with a folding handle, just never came across one to fit.

Few months ago cut off an old 3/8" ratchet handle to make a 4" stubby. The cut off piece has been setting around since, just seemed like the nice knurled piece might be used for something.

Ran into the DP again, Setting at the bench rubbing my ouwy-noted the cut off knurled section. Looked at the cross slide handle. Looked at flop handle on crank clamp. Handle just a slot that's pinned to bolt- wonder if I could make a folding handle? If I cut a slot in end of knurled bar, then pin to piece of flat bar somehow, weld it to bolt to replace the fixed handle on crank...without further thought to details started by assuming a bolt would work as pin.

Drilled tap hole thru bar same distance from end as bars diameter. Then cut off 5/8" section of 1 1/2"x3/16" flat bar, about width of round bar. I'd need to shorten but left long to hold while working on it. Need a hole in it so need to slot the round bar. Once slot cut Ill match drill the flat bar, then enlarge hole to clear 1/4-20, tap the bar, that should works as far as pinning

To cut the slot I used sawzall. Cut one side, old blade was toast by the time I got 5/8" depth. Opps no more metal blades. I also realized I should have drilled hole first for bottom of slot, even if I had another blade, need to clean out material. So opted to use angle grinder to finish slot. Only good thing with the single cut is it gave me a guide to plunge grind, the really scary part was having that much disk down inside bar. Half expecting disk to bind, either rip out bar from vise and throw, yank grinder out of my hands or worse have disk shatter. Went and got my face shield, held on tightly but got it ground out. As it was previously used disk bottom of slot was round, the disk slighter narrower at outer edge. Was going to use a fresh disk to square the slot-but decided if its going to bind it'd be new blade in tapered hole. Went and got a file.

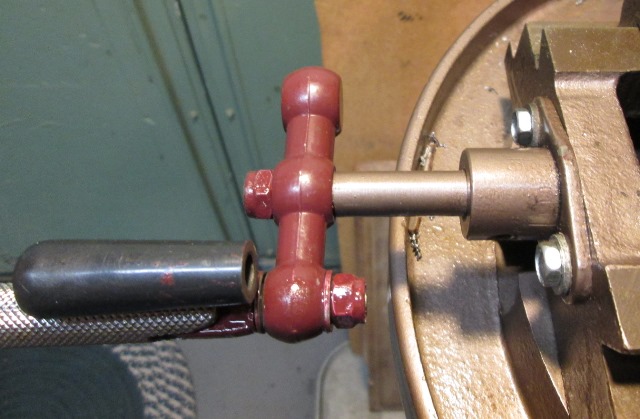

Radius end of bar, match drilled hole thru it,, and plan changed. I was going to tap handle for pivot bolt but using a piece of 3/16" rod bar to pivot flat bar to ensure full pivot worked well.

Decided I could use 3/16" bolt with enough shoulder to get thru and nut or somehow fix a piece of rod. Mute though until/if I make the bolt to attach to handle crank. That was the clincher though, removing the fixed handle from the crank, simple mushroomed ends held it on. Used file to take off its edge. So when I reach that point trying peening length round.

Laying out where to cut what, Cutting off head of bolt, then cut a notch into flat bar to weld together.

Measure twice - cut once- but you have to cut where you last measured-not sure what happened. Shoulder length a good 1/8" shorter than marked, it'll work.

Cut the notch, using washer to keep bead contained and as bearing surface. Don't expect to survive welding intact but need shoulder to stay clean.

Jigged. Hmm but can he weld it? Sketchy. Magnets holding bolt & flat bar in place, piece of brass tube keeping washer flat, using brass bar to hold the flat bar down and to keep splatter off. With a slow blink pulled the trigger applying a long tack...open my eyes- HOO-Hoo! Flip over tack other side then back again to get another on each side. Washer melted a bit but still flat.

Small hole, not pretty but welded. Cut a piece of 3/16" round with about 1/8" sticking out both sides. Laid on vise anvil with opposite end of rod on face and struck with hammer at slight glancing angle @ 1/4 points. Not hitting too hard so hopefully doesn't swell inside. Flipped it over and peened the other side. Then went around making uniform round over. Wow, first time I've ever done this. I assume a lot of luck but rod still spins both in handle and flat bar but still captured. Just a first, pretty cool. Making rivets.

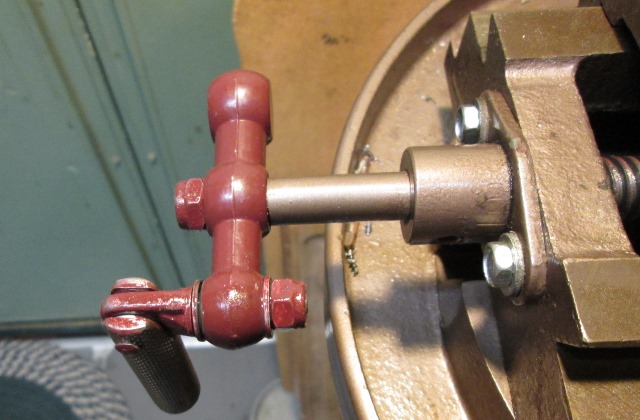

Enlarged the hole in crank handel for the 1/4" shoulder bolt. Placed washer on both sides to cut rotational resistance, nutted with a nylok.

Floppy crank handle! Mounted. Ground the back side of the mounting nylok trying to get more engagement. Thread on this shaft of bottom slide for handle has always been short, maybe 3 threads. Wont stay tight. Looked at cutting back the square drive for handle, cut threads a bit longer. However what I saw is if I elevated the entire cross slide base I could cut off up to a good inch, though probably only go 1/2", recut square and threads. Wouldn't lose slide travel and it would put handle closer to table but still outside.

But more notable, I saw if using a 1/2" piece of aluminum plate as spacer I could add a third T-bolt thru both. Has never offered to moved so not an issue but could. It would also cover the exposed T-bolt slots which is an issue and real motivation. Other than cleaning out shavings, its bits/material being worked on etc falling into the slots and trying to retrieve thru the cross slide. Usually involves moving slide, resetting up. Um definitely Its on the list.

Simple kinda fun project killing an afternoon. Making a floppy handel..

Sort of a before (after the fact) - where it was..

and where it is. I honestly only gained about an inch which does seem to be just enough so its not reaching out and grabbing me as I walk by- we'll see. However impractical, just doing this was worth the effort, led to a project-spacer for base that WILL be practical.

Back to top of page

Back to shop tool mods

Back to Our shops home page